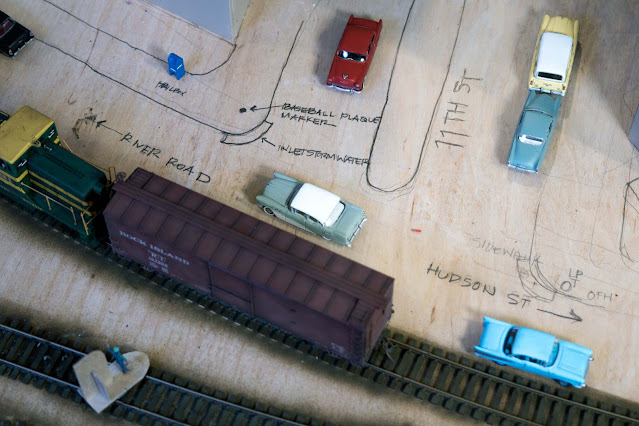

Some new exciting additions to the layout by two very good friends from out of town

The most recent is the first shipment of period Sylvan automobiles from Rick De Candido. The colors are fantastic, and have a great softness to them that are not only era specific, but they also fit so well into the gritty mood of Hoboken I am trying to convey with the layout. Rick should do a clinic on the windshield techniques he's tried and now perfected. The wrap around style of the 50s is especially challenging to the process, and the results are impressive. I'm asking Rick to build as many as he wants to. It's such a luxury to have him doing this!

Also in the first photo is a finely crafted Rock Island boxcar by Rick with great weathering and details (and came in its own special foam lined box!)

|

| Busy corner of 11th and Hudson Streets, Hoboken, NJ in 1959 |

|

The first test build pickup truck across the tracks from Pennsylvania Railroad's Marine ship yard.

Be alert! billboard from a kit I used to produce. |

A few months ago, another very good friend Tom Pearson commented that I could use throttle holders, and then they showed up! These are 3D printed of white PLA with the appropriate logos for the different railroads of the PoNY. At first I thought I'd have to paint the embossed logos in a contrasting color - maybe like pressing into paint like a stamp pad. But it turns out the shadows are more than enough to make the logo legible. The pockets fit both the CVP T5000 and T1300 OPS throttles. One more for the Lehigh Valley 28th Street Station is in the works. I can't tell you how thrilled I am to have customized elements on the layout. It really ties the layout together and makes it a more considered environment. Now I just need to do all of the basics like fascias, scenery, backdrop...!

It's such a pleasure to have the help of good friends. It is a huge boost to my layout morale and inspires me to work on the layout, and it's like being a kid at Christmas when a package arrives. It shows that there are ways to be involved in far-flung layouts in a real and meaningful way. This is especially nice during Covid times when we aren't gathering locally and can't share layout experiences in person.

Being in the same headspace of a layout with someone is a very rewarding experience even when you can't be there physically. With technology making virtual relationships a larger part of our lives, the shared headspace goes beyond empty casual social interactions on social media. It's the part that came along naturally from being together in the physical space of the layout together and talking about the prototype, working on the layout, and operating. Sharing that headspace makes the message more important than the medium, which is the way it should be.

And I think Marshall McLuhan would be OK with that in this case.